A small spherical insulator of mass – Small spherical insulators are fascinating materials that play a crucial role in various electronic devices and applications. These tiny insulators possess unique electrical, thermal, and mechanical properties, making them indispensable components in the world of electronics.

From their use in capacitors and resistors to their applications in thermal management systems, small spherical insulators offer a wide range of benefits and advantages. In this article, we will delve into the fascinating world of these insulators, exploring their properties, manufacturing techniques, and diverse applications.

Definition and Characteristics

A “small spherical insulator” is a small, spherical object made of a material that does not conduct electricity. These materials are characterized by their high electrical resistivity and low thermal conductivity, which means that they do not allow electricity to flow through them easily and do not conduct heat well.

Examples of materials that commonly exhibit these properties include rubber, plastic, glass, and ceramics. These materials are often used as insulators in electrical applications, such as in electrical wires and cables, to prevent the flow of electricity.

Electrical Properties

The electrical resistivity of a material is a measure of its ability to resist the flow of electricity. The higher the electrical resistivity, the more difficult it is for electricity to flow through the material. Small spherical insulators have very high electrical resistivity, which means that they do not allow electricity to flow through them easily.

Thermal Properties

The thermal conductivity of a material is a measure of its ability to conduct heat. The higher the thermal conductivity, the more easily heat can flow through the material. Small spherical insulators have very low thermal conductivity, which means that they do not conduct heat well.

Applications in Electronics

Small spherical insulators find widespread applications in the realm of electronics due to their unique electrical properties and compact size. Their presence in capacitors, resistors, and other electronic components is crucial for ensuring efficient and reliable operation.

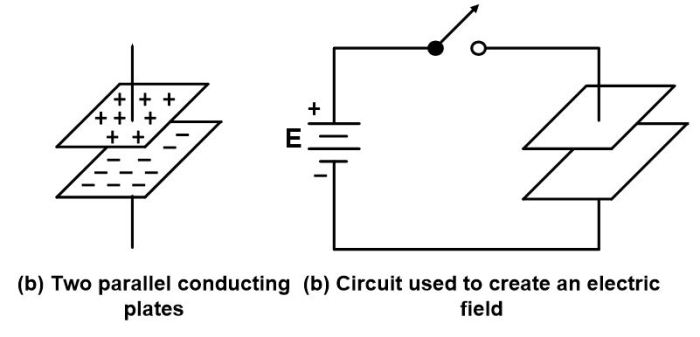

Capacitors

- Small spherical insulators act as the dielectric material in capacitors, separating the conductive plates and preventing direct electrical contact between them.

- The spherical shape minimizes the electric field concentration at the edges of the plates, enhancing the capacitor’s overall performance and reducing the risk of dielectric breakdown.

- The choice of insulator material depends on factors such as the desired capacitance value, voltage rating, and operating temperature range.

Resistors

- Spherical insulators are employed as spacers or supports within resistors, maintaining a consistent distance between the resistive element and the surrounding enclosure.

- Their insulating properties prevent electrical leakage and ensure accurate resistance values.

- The size and shape of the insulators are carefully designed to minimize parasitic capacitance and inductance, which can affect the resistor’s frequency response.

Other Electronic Components

- Small spherical insulators are also utilized in various other electronic components, such as inductors, transformers, and printed circuit boards (PCBs).

- Their insulating properties prevent unwanted electrical paths and ensure the proper functioning of these components.

- The choice of insulator material and design considerations depend on the specific application requirements, including voltage levels, frequency range, and environmental conditions.

Manufacturing Techniques

Small spherical insulators are typically manufactured using one of several techniques, each with its own advantages and disadvantages.

The most common methods include:

Molding

Molding involves shaping molten or pliable material into a spherical shape using a mold. The material is typically a ceramic or plastic compound, which is heated until it becomes pliable and then pressed into a mold cavity. Once the material has cooled and solidified, it is removed from the mold, resulting in a spherical insulator with the desired size and shape.

Extrusion

Extrusion involves forcing a viscous material through a die to create a continuous strand. The strand is then cut into small spherical shapes using a rotating cutter. This method is typically used for high-volume production of small spherical insulators.

Injection Molding

Injection molding involves injecting molten material into a mold cavity under high pressure. The mold cavity is shaped to create the desired size and shape of the insulator. Once the material has cooled and solidified, it is ejected from the mold.

Factors Influencing Size, Shape, and Properties, A small spherical insulator of mass

The size, shape, and properties of small spherical insulators are influenced by several factors, including:

- Material composition

- Mold design

- Processing parameters (temperature, pressure, etc.)

- Post-processing treatments (annealing, grinding, etc.)

Electrical Properties

Small spherical insulators exhibit unique electrical properties that stem from their shape and material composition. Their dielectric constant and breakdown strength are crucial factors influencing their performance in various electronic applications.

Dielectric Constant

The dielectric constant, denoted by ‘ε’, represents the ability of an insulator to store electrical energy. For small spherical insulators, the dielectric constant is influenced by the material’s polarization properties. The higher the polarization, the greater the dielectric constant. Factors like temperature, frequency, and material impurities can affect the dielectric constant, altering the insulator’s ability to store electrical energy.

Breakdown Strength

Breakdown strength refers to the maximum electric field an insulator can withstand before it allows current to flow. For spherical insulators, the breakdown strength is determined by the material’s composition and the insulator’s shape. The spherical shape distributes the electric field more uniformly, reducing the likelihood of electrical breakdown compared to other shapes.

The material’s electrical resistivity and dielectric strength also play a crucial role in determining the breakdown strength.

Thermal Properties

Small spherical insulators exhibit unique thermal properties due to their shape and material composition. Their spherical geometry minimizes surface area, reducing heat transfer by conduction and convection. Additionally, the choice of insulating materials, such as ceramics or polymers, significantly influences their thermal conductivity and heat capacity.

Thermal Conductivity

Thermal conductivity measures the ability of a material to conduct heat. Small spherical insulators typically have low thermal conductivity, hindering heat flow through them. The spherical shape minimizes the path for heat transfer, while the insulating materials further impede heat conduction.

This property makes these insulators effective in applications where heat dissipation is critical.

Heat Capacity

Heat capacity represents the amount of heat required to raise the temperature of a material by one degree Celsius. Small spherical insulators generally have low heat capacity due to their small mass and low thermal conductivity. This means they can absorb or release relatively small amounts of heat without experiencing significant temperature changes.

Applications in Thermal Management Systems

The thermal properties of small spherical insulators make them valuable in various thermal management systems:

Heat Sinks

They can be incorporated into heat sinks to enhance heat dissipation from electronic components.

Thermal Insulation

They provide effective insulation in applications requiring thermal isolation, such as cryogenic systems and high-temperature environments.

Thermal Storage

Their low heat capacity allows them to store and release heat efficiently, making them suitable for thermal energy storage systems.

Mechanical Properties: A Small Spherical Insulator Of Mass

Small spherical insulators exhibit unique mechanical properties due to their shape and material composition. Their spherical shape provides isotropic strength, meaning they can withstand forces applied from any direction. The material composition, typically ceramic or glass, contributes to their high compressive strength and resistance to wear and tear.

Strength

The compressive strength of spherical insulators is significantly higher than their tensile strength. This is because the spherical shape distributes applied forces evenly, preventing localized stress concentrations. The material composition also plays a crucial role in determining strength. Ceramic insulators, such as alumina or zirconia, possess high compressive strength, while glass insulators have lower strength but better electrical properties.

Toughness

Toughness refers to the ability of a material to resist fracture under impact or sudden loading. Spherical insulators generally exhibit moderate toughness due to their inherent brittleness. However, the addition of toughening agents, such as zirconia or silicon carbide, can significantly enhance toughness without compromising other mechanical properties.

Wear Resistance

Spherical insulators are often used in applications where they are subjected to abrasive wear. The spherical shape minimizes contact area, reducing friction and wear. The material composition also influences wear resistance. Ceramic insulators, with their high hardness, provide excellent wear resistance, while glass insulators are more susceptible to wear due to their lower hardness.

Quick FAQs

What are the common materials used to make small spherical insulators?

Common materials used to make small spherical insulators include ceramics, plastics, and glass.

What are the advantages of using small spherical insulators in electronic devices?

Small spherical insulators offer several advantages, including their high electrical resistivity, low thermal conductivity, and excellent mechanical strength.

How are small spherical insulators manufactured?

Small spherical insulators can be manufactured using various techniques, such as molding, pressing, and sintering.